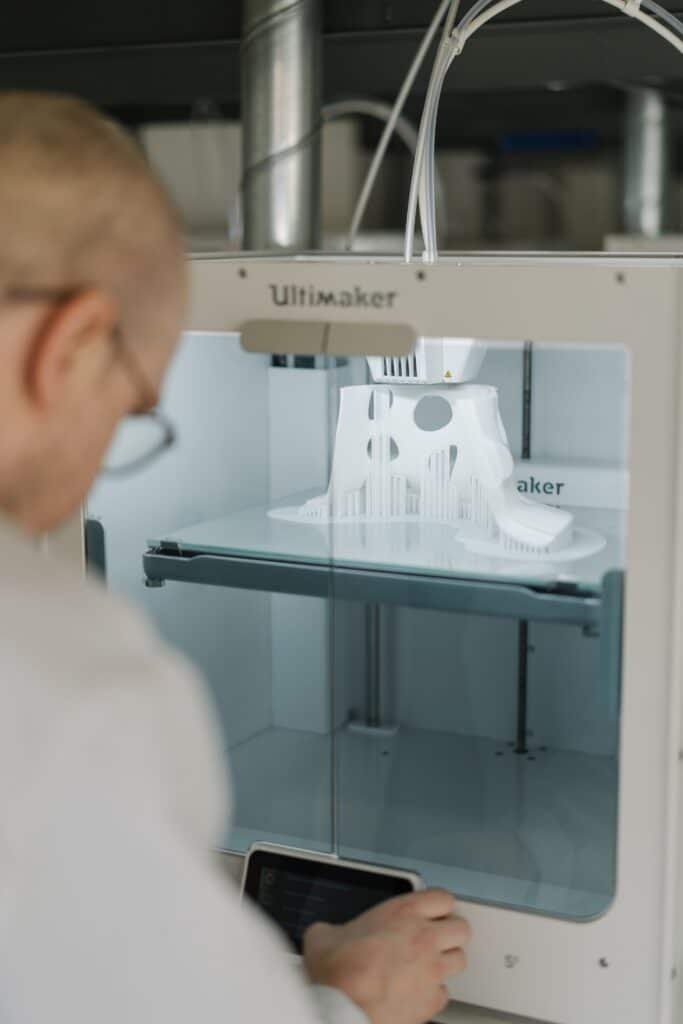

The choice of filament material plays a crucial role in determining the success and quality of printed objects. Among the plethora of options available, PETG (Polyethylene Terephthalate Glycol) filament has emerged as a popular choice for its balance of strength, durability, and ease of use. This article delves into the composition, properties, and applications of PETG 3D printer filament, shedding light on what makes it a preferred material for a wide range of printing needs.

Composition of PETG Filament

PETG filament is derived from a thermoplastic polymer known as polyethylene terephthalate glycol. This polymer is a member of the polyester family, which includes commonly known materials such as PET (Polyethylene Terephthalate), used in water bottles and food containers. The addition of glycol to PETG improves its properties, making it more suitable for 3D printing applications.

The chemical composition of PETG filament typically includes:

- Polyethylene Terephthalate (PET): The base polymer, PET, provides the backbone of the filament. It offers excellent chemical resistance, toughness, and dimensional stability.

- Glycol Modification: The addition of glycol molecules enhances PET’s characteristics, particularly its flexibility, impact resistance, and ease of processing. This modification results in PETG, a material with improved properties compared to conventional PET.

- Additives: Manufacturers may incorporate various additives to modify specific properties of PETG filament. These additives can include colorants for aesthetic purposes, UV stabilizers to enhance weather resistance, or additives to improve adhesion to the print bed.

Properties of PETG Filament

PETG filament boasts a diverse set of properties that make it suitable for a wide range of applications. Some key properties include:

- Strength and Durability: PETG is renowned for its impressive strength and durability, making it suitable for printing functional prototypes, mechanical parts, and end-use products. It exhibits good impact resistance, reducing the likelihood of breakage or deformation.

- Flexibility: The glycol modification imbues PETG with a degree of flexibility, allowing it to bend without breaking. This property is particularly beneficial for applications requiring parts that can withstand bending or flexing.

- Chemical Resistance: PETG demonstrates excellent resistance to chemicals, including oils, greases, and alcohols. This makes it suitable for applications where exposure to various substances is expected, such as industrial components or chemical containers.

- Transparency and Clarity: PETG filament is inherently transparent, providing optical clarity similar to glass. This property is advantageous for applications where visual aesthetics or transparency is desired, such as in display cases or light fixtures.

- Ease of Printing: PETG is relatively easy to print with, offering good adhesion to the print bed and minimal warping compared to materials like ABS. Its low shrinkage during cooling contributes to improved dimensional accuracy and overall print quality.

- FDA Approval: PETG is approved by the FDA (Food and Drug Administration) for certain food-contact applications, making it suitable for printing utensils, containers, and other food-safe items.

- Temperature Resistance: PETG exhibits moderate temperature resistance, with a glass transition temperature (Tg) typically ranging from 70°C to 80°C. While not as heat-resistant as materials like ABS or polycarbonate, PETG can withstand moderate temperatures without deforming.

Applications of PETG Filament

The versatile properties of PETG filament make it suitable for a wide array of applications across various industries. Some common applications include:

- Prototyping: PETG is often used to create functional prototypes for product development and testing. Its strength, durability, and ease of printing make it an ideal choice for engineers and designers looking to validate their designs before mass production.

- Mechanical Parts: The robust nature of PETG makes it well-suited for producing mechanical components, such as gears, brackets, and housings. Its excellent dimensional stability ensures that printed parts maintain their shape and integrity under load.

- End-Use Products: PETG is increasingly being used to manufacture end-use products, including consumer goods, electronic enclosures, and household items. Its combination of strength, flexibility, and chemical resistance makes it suitable for producing durable, functional items for everyday use.

- Cosplay and Props: PETG’s transparency and ease of printing make it a popular choice for crafting cosplay props, costume accessories, and decorative items. Its ability to hold intricate details and accept post-processing techniques like painting and sanding further enhances its appeal in this application.

- Medical Devices: PETG’s FDA approval and biocompatibility make it suitable for certain medical applications, such as prototyping medical devices, laboratory equipment, and patient-specific tools.

- Educational Projects: PETG’s ease of use and reliability make it an excellent choice for educational settings, where students can learn about 3D printing technology by creating projects ranging from simple models to functional prototypes.

- Packaging and Containers: PETG’s chemical resistance and transparency make it suitable for packaging materials and containers for various products, including cosmetics, pharmaceuticals, and chemicals.

PETG filament offers a compelling combination of strength, durability, flexibility, and ease of printing, making it a versatile choice for a wide range of 3D printing applications. Whether you’re prototyping new designs, producing end-use products, or crafting cosplay props, PETG provides the reliability and performance needed to bring your ideas to life. With its diverse properties and FDA approval for food-contact applications, PETG filament continues to be a favored material among hobbyists, professionals, and manufacturers alike, driving innovation and creativity in the world of 3D printing.