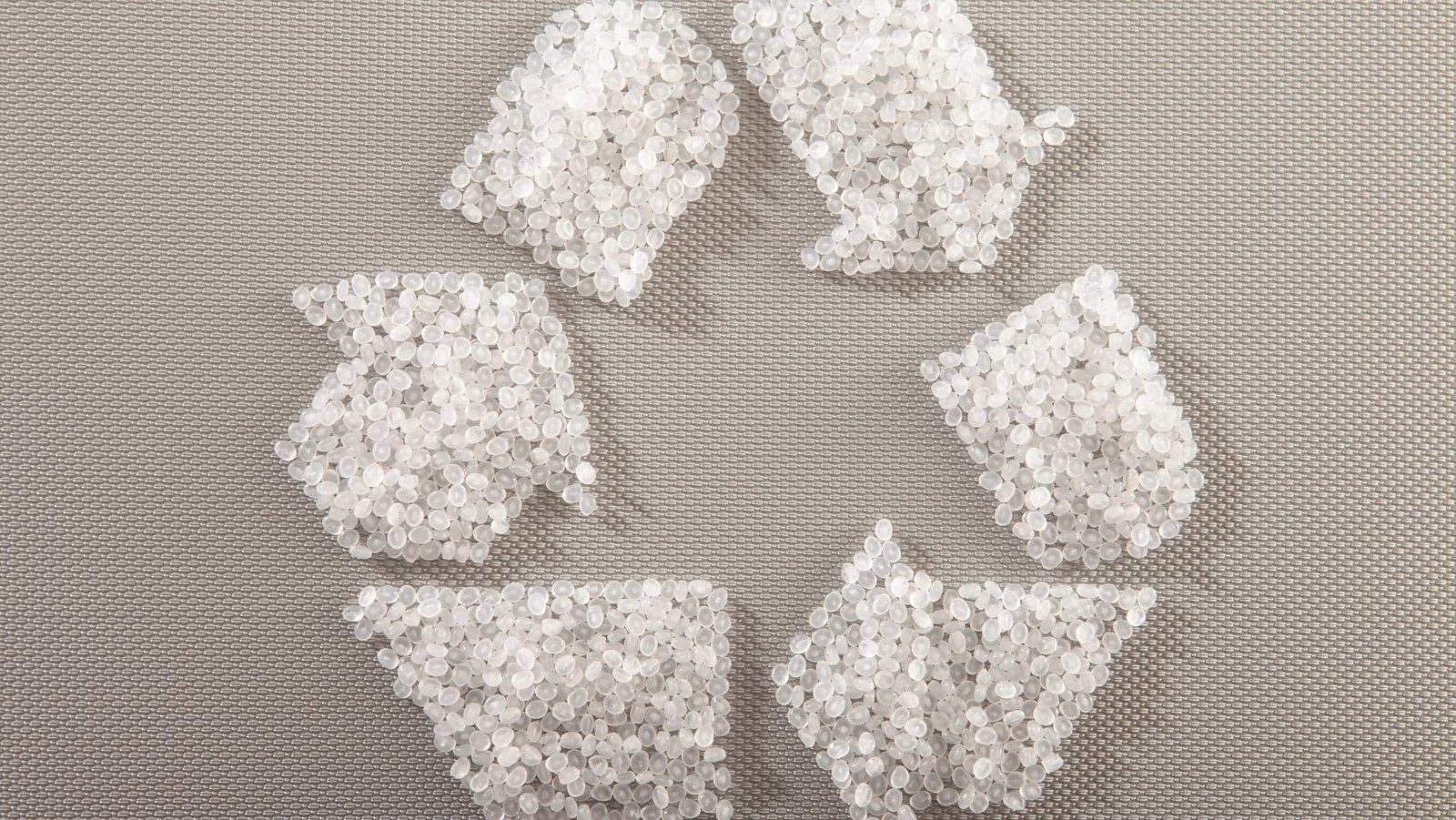

As 3D printing continues to evolve, so does the conversation around sustainability and environmental impact. An important aspect of this dialogue is the recyclability of 3D printer filament. Many enthusiasts and industry professionals are eager to explore whether these materials can be recycled, reducing waste and contributing to a more eco-friendly approach. In this article, we will delve into the feasibility of recycling 3D printer filament and the initiatives underway to make this process more accessible.

The Composition of 3D Printer Filament

To understand the potential for recycling, it’s crucial to first examine the composition of 3D printer filament. Filaments are commonly made from materials such as PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol), and others. Each material has unique properties, and their recyclability depends on the specific polymer and any additives used in their production.

Recycling PLA Filament

PLA is a biodegradable and compostable material derived from renewable resources like cornstarch or sugarcane. PLA filament can be recycled through a process called mechanical recycling, where it is melted, re-extruded, and formed into new filaments. However, it’s important to note that the quality of recycled PLA may not always match that of the original filament, and there may be limitations on the number of recycling cycles it can undergo.

Challenges with Recycling ABS and Other Filaments

Filaments like ABS, which are commonly used in 3D printing, pose challenges for traditional recycling methods. ABS is not easily biodegradable, and its recycling process typically involves chemical methods, which can be complex and costly. Additionally, ABS recycling may result in the loss of certain properties, making it less suitable for some applications.

Initiatives and Solutions

- Closed-Loop Filament Recycling:

Some companies are exploring closed-loop recycling systems, where they collect used filaments from customers, reprocess them, and provide the recycled material back to the users. This approach aims to create a sustainable and circular system for 3D printing materials. - Filament Extruders:

Filament extruders, designed for home or small-scale use, allow individuals to recycle their own 3D printer waste. These devices grind down used prints, melt the plastic, and extrude it into new filament. While this approach may not be as refined as industrial processes, it empowers users to contribute to a more sustainable 3D printing ecosystem. - Biodegradable Filaments:

Beyond recycling, the use of biodegradable filaments like PLA provides an alternative approach to reducing environmental impact. These materials break down naturally over time, mitigating the long-term accumulation of 3D printing waste.

The question of whether 3D printer filament can be recycled is met with both challenges and promising solutions. While the recycling landscape for certain filaments is still evolving, initiatives and technologies are emerging to make 3D printing more sustainable. As the demand for eco-friendly practices continues to grow, the industry is likely to witness further developments in filament recycling methods, fostering a greener and more responsible approach to additive manufacturing.